Kavach2020 (Archived)

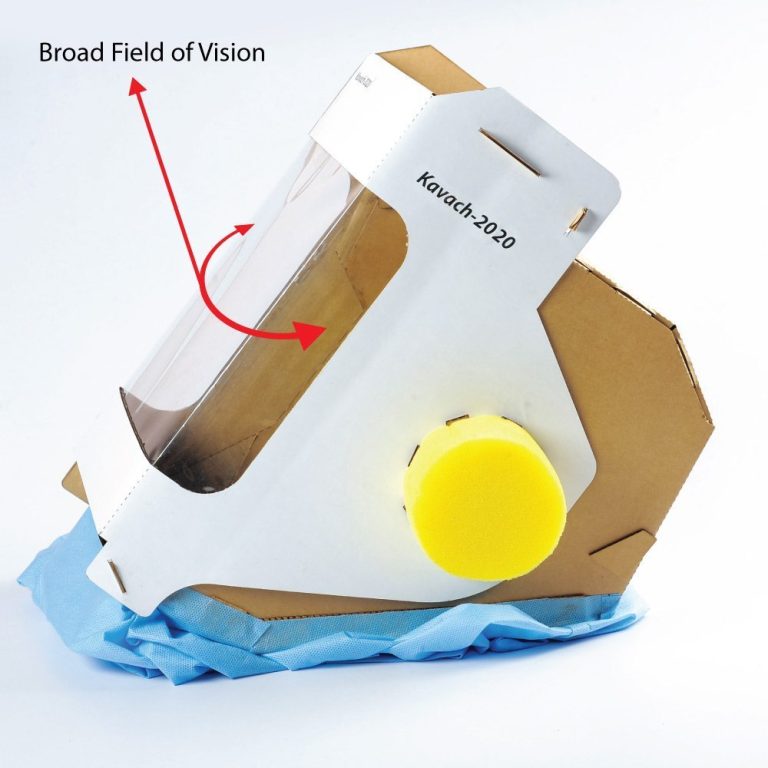

Kavach2020 Cardboard Face shield. First time in the world, a face shield made out of cardboard, that is light, provides wide field of view and has good ventilation. We have designed this shield using industrial design tools and techniques, the same technologies we used to make cardboard drones.

Though we do not make Kavach2020 anymore, we have kept this page published for information.

Why Cardboard

Corrugated paper board is a versatile material, it can be bent and broken to accommodate many shapes, it is cost effective, it is scalable and sustainable. It came up as our natural choice.

We have designed this shield using industrial design tools and techniques, the same technologies we used to make cardboard drones. We are now closely working with vendors who can provide necessary quality and quantity of the raw materials.

Our Mission

To make a face shield that meets the following criteria

Better protection

Convenience to the user

Uses sustainable materials

Cost effective

Scalable for large scale production

Broad Field of View

See and be seen

Writable Surface

Plain paper, the ultimate differentiator.

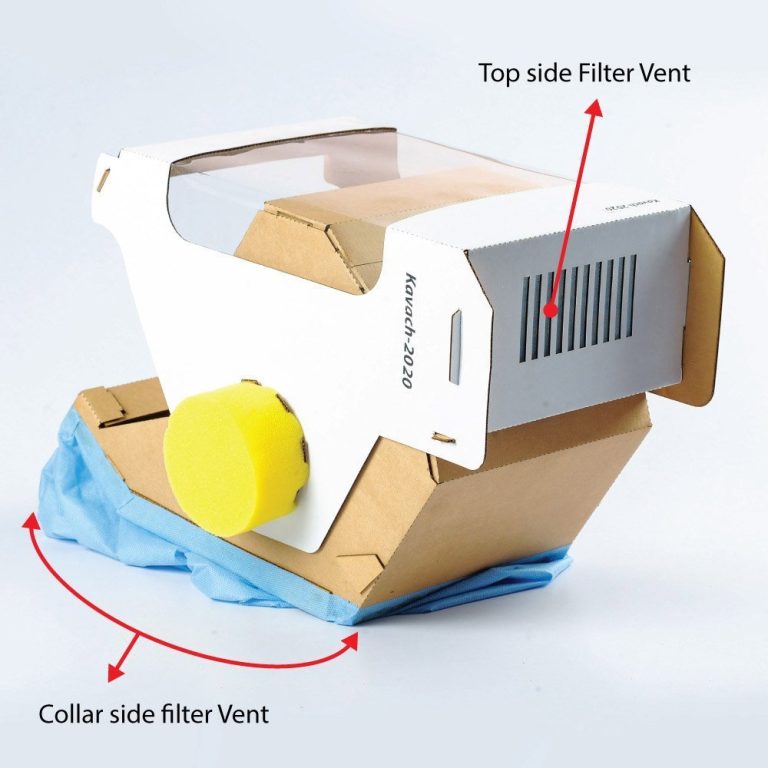

Dual air vents

Breath in and breath out

Retractable face cover

Safe and Flexible

Ergonomic Handle

Do it in style

Snug Fit Foam Buns

Fits like a charm

Aural Communication

Converse with ease

Dual Head Cushions

No hard contacts

Functional

Kavach2020 can be worn with other accessories such as spectacles, masks, earphones and works with facial biometric devices and infrared thermometers. The shield can be retracted to allow small breaks such as drinking water.

Best in class Industrial Design

Using our experience in making cardboard drones we developed Kavach2020, a face shield made out of cardboard, that is light, provides wide vision and has good ventilation

Lighter than you can notice

At around 350 grams, it weighs about as much as a pair of headphones. The light weight shield provides better thermal comfort than fully enclosed plastic face shields. it causes negligible fogging, is odorless and offers a fair degree of freedom of movement.

Technical Specifications

Fully assembled shield

Width : 240 mm

Depth : 280 mm

Height : 350 mm

Top side vent : 2 plys of 45 GSM Non-woven antimicrobial fabric

Collar side vent fabric : 45 GSM Non-woven antimicrobial fabric

Foam Buns : 100 ppi synthetic foam

Weight : 350 grams (+/- 5%)

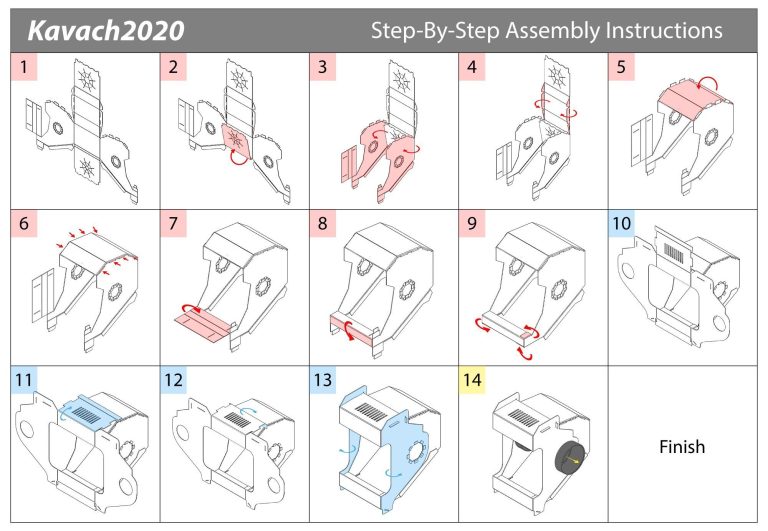

Assembly and Usage

The shield is made up of three functional units, and can be assembled as per the pictorial instructions provided along with the package.

Once the shield is assembled, it is worn like a t-shirt, head first with the face cover in retracted position.

- The shield is worn by passing the non-woven collar of the shield through the top of the head.

- It is adjusted by pulling the two foam buns over to the ears to maximize user’s comfort.

The face cover of the shield can be put in place or retracted by using the ergonomic handle of the face cover.

That’s it

A little Back Story

At the onset of lockdown due to coronavirus, we considered donating few face shields to frontline workers, we realized that making of 3D printed shields does not scale well, each print takes an hour or two, 100 shields would take us between 5 to 10 days. We said to ourselves, there has to be another way. In a span of 30 days our team iterated over a hundred designs and constructed prototypes to develop this workable model.

Kavach2020 Development in Pictures.

What it is not

It is not 3rd party tested and certified for antiviral filtration efficacy

It is not waterproof

It is not fireproof

It is not a respirator

It is not a helmet

What it is

It is a cardboard face shield

It will filter dust, and to an extent microbes

It requires some assembly